DCS Announces New Release of QDMWEB with Scanned Data Management and Analysis

Dimensional Control Systems has released QDMWEB QualityScan with new features that support fast and visual analysis of scanned data.

QDMWEB QI manufacturing quality management system gives access to quality information from anywhere, at any time, instantly. Using Quality Intelligence, QDMWEB QI automates your quality collection and reporting, helping manufacturers reduce their costs with real-time monitoring and powerful SPC tools.

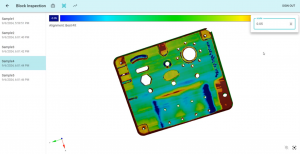

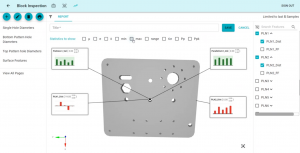

The new version of QDMWEB QualityScan expands QDMWEB QI to manage, analyze, and report on scanned data using visual 3D CAD, Statistical Process Control, and customizable quality metrics. This expansion provides the ability to view statistics on 3D CAD with SPC charts on demand, and to create localized root cause reports with CAD as a means to bring all stakeholders onto the same page for problem solving, drastically improving the time to find the source of issues and resolve them in manufacturing.

Furthermore, this new update gives QDMWEB the ability to use a single system to collect and analyze scan data from multiple scan systems with an interactive portal to navigate and view the scan data as a 3D color map, SPC report, and custom views. These results can be queried and compared to any other scan results, allowing for fast analysis of before and after quality from machine changes, supplier changes, process updates, and more. With added sensitivity analysis to highlight the highs and lows of scanned parts, QDMWEB QualityScan provides an enhanced view of the scanned results for faster and more accurate analysis.

“As technology advancement accelerates, and more advanced inspection methods become accessible to more manufacturers, it is important to have a system that can bring all of this quality data together, standardize it, and make it actionable to the teams that need to use it,” said Thagu Vivek, Director of Quality Management Systems at DCS. “As our clients implement more advanced processes, it is imperative that we support those efforts with new updates to QDMWEB to meet the growing demand for centralized data management.”

QDMWEB QI and QDMWEB QualityScan are both available from Dimensional Control Systems, DCS. To learn more, visit https://www.3dcs.com/qdmweb-qi-spc-quality-management-platform. For a free demonstration of the new features, contact DCS at https://mkt.3dcs.com/contact-us.

Benjamin Reese

Dimensional Control Systems

email us here

Visit us on social media:

Facebook

X

LinkedIn

YouTube

Other

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Consumer Goods, Electronics Industry, Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release