CORONET METAL’S US MODULAR CONTAINERIZED STRUCTURE OF BUILDING FOR DRY MINING ORE CONCENTRATION

In plant design, particularly in the mining sector, Coronet Metals US has evolved the modular approach of container - based structure of building.

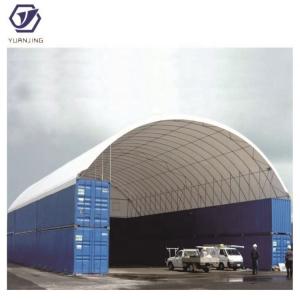

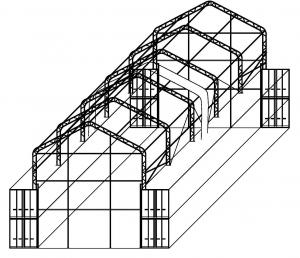

BEATTY, NEVADA, UNITED STATES, June 27, 2021 /EINPresswire.com/ -- In plant design, particularly in the mining sector, Coronet Metals US has evolved the modular approach of container - based structure of building. For several years, modular mineral processing facilities have been used in a wide range of industries. When the working site is very distant, site access and area are limited, the work plan requires plant modules to be built in parallel, and/or the plant has a short lifetime at one site and will then be shifted to another site, a modular concept will typically be decided to adopt in terms of the original site constructed plant method. We're employing high-cube container frame of about 20-foot or 40-foot. The height and the width of the structure will be 28 and 100 feet, respectively. The corners casting, which has a design patent, may be plugged into the bottom rail, post, and cross structure by tightening bolts instead of welding. Pre-assembly parts can reduce the shipment volume to the facility. The processing machine will be housed within a container, that is double or triple stacked on side, that takes only a few days to install.The foundation construction of the mining plant, design requires a lot of money and work, specifically in flat land like deserts in Nevada, Arizona, and New Mexico. For minor to big plants, the industrial revolution is the first container - based enclosure for the USA's foremost dry concentration facility, that will be built near Beatty, Nevada.

CORONET METAL’S US CONTAINERIZATION: FAR BEYOND THE CONVENTIONAL MODULAR PLANT IN BUILDING

The benefits of plant modularization, especially in the mining industry can be enhanced in some situations by containerizing the plant components. These are the circumstances, where transportation expenses account for a significant percentage of the overall costs throughout the product ’s life cycle. While ensuring acceptable high plant operational capability and reliability, this strategy aims to reduce the transportation costs and enhance ease of access and site assembly.

WHY CORONET METAL’S US MODULAR CONTAINERIZED BUILDING IS DESIRABLE?

Employee accommodations are frequently required for distant mining sites, mineral and geophysical investigation, research centers, as well as other economic interests. Coronet metal’s us modular containerized buildings are a preferable solution for creating modular, employee residential buildings or full distant camp facilities in certain circumstances, where Access to housing is lacking or inadequate.

The following are some examples of project criteria that may make a modular approach desirable:

• Extremely distant places that could make a modular approach appealing.

• Comparatively small aspect of project management

• Project test / experimental facilities

• Limited working life

• Multiple mining sites, each with its own reasonably short life span

• Progressive improvement in output capacity

WHY CORONET METALS US MODULAR CONTAINERIZED STRUCTURE?

If you're searching for a convenient and simple approach for a perfect short term solution to handle your personnel, look no further than a coronet metal containerized structure. We are innovators in the design, manufacture, and installation of high-quality, high-cube modular container frames that can be used as offices, healthcare facilities, schools, construction site workplace, overnight accommodation, shower and toilet facilities etc. These units are particularly well-suited to businesses involved in the mining, gas, and oil industries as well as public economic development.

The advantages of our containerized modular design are numerous, they are quickly manufactured, constructed, and delivered to clients, whilst being safe, robust, eco friendly, and affordable. Container steel is reusable, resulting in lower energy use and pollution. Furthermore, containers are often built at a factory, shipped to building sites, and swiftly erected, following a standardized design and construction procedure that is simple to manage and construct. Moreover, depending on the site planning needs, containers can take a number of shapes. Containers are employed, not just for mining purposes, but also for public buildings, disaster relief housing, fields, and military projects.

CONSTRUCTION, SUPPLY, AND PLACEMENT OF FULLY OUTFITTED CONTAINERIZED STRUCTURES.

According to the demands of your project, we may employ containerized building models to develop modular structures of various heights. The modular structures may be linked horizontally to create larger rooms or placed one on top of the other to generate two structures. Modular structures are typically one or two stories high. You will save money on marine and land shipping expenses due to the unique packing of containerized construction models. A single 40-foot container for transportation, for example, can convey 140 m2 of conventional structures. We can use the containerized building models to create modular buildings of several levels, according to the needs of your project. The modular structures can be joined horizontally to form large spaces or stacked one on top of another to construct individual components. Modular structures are generally designed with one or two levels.

James Gim

Coronet Metals US Inc,

jgim@coronetpm.com

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.