Five Axis CNC Machining for Turbocharger Impeller

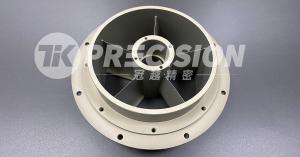

5-axis CNC Milling and turning machining is used for machining complex surface 5-axis machined part. Custom impeller & Custom turbo.

BOSTON, COMMONWEALTH, USA, April 8, 2021 /EINPresswire.com/ -- An impeller is a rotor inside a tube or conduct used to increase (or decrease in case of turbines) the pressure and flow of a fluid. Impeller is the heart of turbocharger. Impeller is on turbocharger’s rotor, it has very complicated structure. When turbocharger operates, impeller will press as much purified air into the cylinder, transform into kinetic energy to improve the engine output. During the process, impeller spins fast, and the tangential speed of rim is fast. The flow situation in the impeller is complicated, and usually under high temperature, high pressure and corrosive environment. Integral impeller design and quality have a crucial impact on the turbocharger’s performance.1. Five Axis CNC Machining for Turbocharger Impeller

5-axis CNC Milling and turning machining is used for machining complex surface 5-axis machined part. It has a decisive impact on aircrafts, aerospace, scientific research, precision equipment, high-precision medical equipment, optical equipment, environmental protection and other industries. At present, a 5-axis CNC machining center is the only method to solve the machining of the impeller, blade, Marine propeller, heavy generator rotor, turbine rotor, large diesel engine crankshaft and so on.

2. High technical requirements for turbocharger impeller machining

This is very difficult to produce turbocharger impeller as complex shaped and structure

The additional movement available with 5-axis machining allows you to achieve complex shapes and designs, 5-axis technology completes the impeller in a single setup, reducing the number of setups and helping you save time. and create multiple and complex shapes without losing the precision, and also helping you achieve a better surface finish.

3. Tighter tolerances can be specified

Our engineering team is capable of executing complex turning and milling operations, including bore profiling, V-band formation, and trepanning, To achieved tighter tolerances for these parts. These turbocharger Impeller are manufactured from 5 axis machining center, heat resistant materials to within ±0.002" tolerances, then laser marked, assembled, and quality checked in accordance with ISO9001

Custom Impeller

Our firm sticks on the theory of 'Quality will be the life in the enterprise’. For Custom CNC Machining Turbocharger Impeller, the manufacture of complex rotational parts with multiple blades, such as blisks and impellers, as well as individual blades, require complex 5 axis milling. Tik precision offers its own impeller/blisk and turbine package for components used in aircraft engines, turbomachinery and power generators.

●Tik precision engineers have extensive experience and knowledge of vane grinding through direct involvement on bespoke customer projects.

●5-axis machining has featured in high efficiency and high precision; Single setup helps save time and money.

●It not only shortened the time but also greatly improved machining tolerance, standard tolerance of components is +/- 0.005 inches, and tighter tolerances can be discussed

●For turbocharger impeller grinding, the work piece is made from a high temperature resistance alloy, which makes it difficult to grind.

●Tik Precision are experts at customizing this precision grinding process to suit your needs.

●5-axis machining helps create surfaces with a quality finish.

To achieved the high technical requirements, we will encounter some problem during the machining.

1. To avoid chatter marks, we need to change the sharpness of the cutting tool, but it will have burr on the surface, to ensure the best surface effect, we need to use the high Hardness and sharpness of the cutting tool.

2. During the processing of the turbocharger impeller, sometime we will find the length of the cutting tool is not enough, and small space between two blades, and diameter of the cutting tool is too small for angle processing, cutting tool will be broken easily.

3. The surfaces of turbocharger impeller are the freedom surface, shape of the blade is irregular. It is high processing difficulty; Thus, it is difficult to keep the uniformity of the surface.

4. Turbocharger impeller is high-speed running in practice, to prevent the vibration and noise. It raised requirements for the machine and cutting tool, we need to save process time and ensure the stationarity and symmetry.

How does Tik precision produce a turbocharger impeller?

It required very precise for the production of turbocharger impeller from the 3D drawing to finished product. For a turbocharger impeller to operate correctly, it is quite essential to know clearly about the operation of the turbocharger.

3D mold design

The design specifications are developed according to the standards and then the

3D model is created by the help of commercial software. Our engineers reviewed, identified, and actions for improvement documented during Pre-production meeting for critical quality and safety

Processing scheme of impeller

Confirm the processing scheme of blades. Make the production order and send it to the production department by production management system.

Finishing and Post-processing of the impeller

Use the 5 axis high precision machining center for the processing of the turbocharger impeller.

Custom turbo

●Work pieces are not moved through several workstations, they can be completed on the 5 Axis machine alone—finishing components with greater accuracy

●Less fixture preparation—saving time and money

●Single setup required for machining complex shapes—increasing productivity

●Can use shorter cutting tools—producing higher cutting speeds and fewer tool vibrations for higher precision.

●Ability to achieve outstanding surface finishes—improving overall part quality

Contact Tik precision for more information

We specialized in precision parts and components machining to serve the electronics, automotive parts, astronautically parts, medical appliances and hand tool industries. Moreover, widely range of design and manufacturing including custom cnc machining, cnc machined parts, non-standard machine parts, machined casting parts and precision turned parts that the materials of hardware parts are in steel, stainless steel, brass, aluminum and plastic.

If you have special requirement about the parts material, tolerance, process, treatment,

Equipment or test, such as seamless copper fin tubing, aluminum alloy 535 casting, and

Glass-lined alloy casting, special paint painting, 5 axis centers, 3D Coordinate

Measurement Machines (CMM) test ... just feel free to contact us, we will try our best to

Meet the needs of you.

Tikprecision

Tik Precision Manufacturing Co.,Limited

+86 186 6620 2010

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

5 axis cnc machining custom turbo

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.